The textile industry has been a major contributor to pollution in the past few years. The textile industry’s pollution has caused environmental issues.

Since the last few years, textiles have been a major contributor to pollution. The textile industry’s pollution has caused an increase in environmental issues. The textile industry must also be modified in terms of the raw materials, production methods, services, and afterlife to reduce the negative effects on climate.

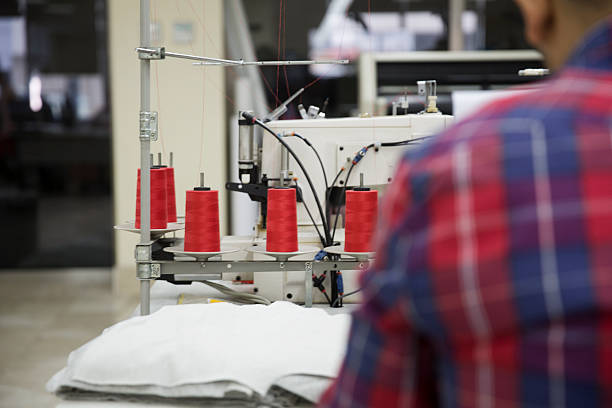

The use of waterless dyeing and closed-loop production, as well as circular fashion, have all been used to reduce the environmental impact of textile manufacture. Garment manufacturing involves a variety of steps, including spinning, weaving and knitting, wet preparatory processes, printing and Dyeing, assembly, packaging, and finishing. During this entire cycle, clothing is treated with various chemicals which are toxic by nature. Each operation increases energy and water consumption.

As follows, there are several ways to reduce the environmental impact of textile manufacturing industries.

*Sustainable Raw Materials: Raw materials are responsible for a significant amount of environmental damage. Cotton production requires a large amount of water, fertilizers, and land. Silk, on the other hand, leads to global warming, depletion of resources, and the use of artificial fibers. Polyester, for example, is not biodegradable. In order to reduce the impact of textile and apparel production, alternative materials have been developed, such as hemp, stinging-nettle fibers, coffee-ground fibers, pineapple fibers, banana fibers, orange fibers, and lotus fibers. In addition, the consumer needs to be educated about sustainability. This can be done through campaigns in shops or tags on clothing. It is possible to inform the consumer only to buy what they need and choose more sustainable options.

Waterless Dyeing: is a method of dyeing textiles with less energy and water than traditional techniques. It produces vibrant colors for both solids and prints. It requires less time, chemicals, and auxiliaries.

* Closing loop production: The closed loop production cycle comprises the designing, display, and usage of a product. The product is circulated in society as long as it can. This also includes the reuse of waste material created during the production of additional products, as well as the use of recycled items to develop new products.

* The circular fashion concept: A circular fashion approach is a process that focuses on waste reduction rather than the linear take-make-waste concept. Clothing that is no longer needed can be recycled or sold as second-hand.

*4Rs (Reuse, Reduce, Repair, and Resale). About 90% of textiles discarded by consumers can be recycled. Technology has made it easier to do this.

Restoring a damaged garment can increase its lifespan.

After wearing clothes, resell or donate them. These small steps can help us achieve sustainable fashion. The greenhouse gas emissions could be reduced to a large extent if the number of garments worn was increased.

* Fast fashion: Fast fashion is a concept that supports manufacturing in a way that respects people, the environment, and animals. Slow fashion is based more on quality than time. It encourages small-batch collections and zero-waste and unifies sustainability and ethics.

Automated Manufacturing: Automation involves the use of computers for the control process, which reduces the need for human intervention and increases product quality. This also allows for the possibility of local production and facilitates transportation, which reduces pollution and the need to off-shore. Sewbots are one example, as well as 3D printing and fully automated manufacturing facilities.

Conclusion:

Animals’ lives and lands are at risk. It is, therefore, essential to use eco-friendly methods that produce less pollution and waste and require fewer resources.